Artificial flowers and succulents must not only be beautiful, but also withstand the test of time and accidents. How can PP materials ensure that your decorations are timeless through their inherent mechanical properties?

Why PP is idea for fake flower?(Plasticity, lightness, Eco-friend).

In this article, I will show the material-level strength tests result based on our artificial flower material PP, including Tensile Strength, Tensile Modulus, Tensile Elongation, Flexural Strength, Flexural Modulus, Specific Gravity and ISO Impact-N. There are relevant test standards and test data, and you can also download the test report of the PP material for free.

1.Preparation and Test Criteria For PP Material

1.1 drawing prepare

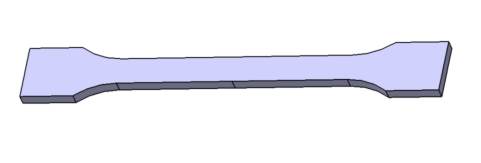

We use Catia to create the 3d model for the pp test piece, we need the dumbbell shape to perform the test.See the below picture, and you can also download the 3d file mode and the 2d dwg drawing for free.

1.2 real test part cut in shape

We cut the PP material per drawing design as below

1.3 test Criteria

Tensile Properties (Strength, Modulus, Elongation): ASTM D638

Flexural Properties (Strength, Modulus): ASTM D790

Specific Gravity: ASTM D792

Impact Strength (ISO Notched): ISO 180

Test condition environment: “25°C, 50% RH” [test in our internal lab]

2.Test data analyse

2.1 Tensile Properties – Balance between tensile strength and flexibility

We test 3 piece,below table show the tensile strength test result.

| 1.Tensile Strength Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | ≥3045psi | 3098 | Pass |

| 2# | 3118 | Pass | |

| 3# | 3127 | Pass | |

Tensile Strength (psi): ≥3045psi– The ultimate ability of a material to resist being pulled apart. Why it’s important: Ensures that leaves and stems are not easily broken when hanging or accidentally pulled, ensuring structural integrity.

Below is the tensile modulus test data,we also test 3 parts.

| 2.Tensile Modulus Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | ≥0.1E6 | 0.15E6 | Pass |

| 2# | 0.2E6 | Pass | |

| 3# | 0.14E6 | Pass | |

Tensile Modulus (x 10⁶): ≥0.1 E6– The ability of a material to resist elastic deformation (stiffness) in the initial stage of stretching. Why it’s important: The moderate modulus allows PP to have a certain degree of “stiffness” to maintain its shape, but not too rigid and brittle. Comparison: Much lower than metal/ceramics, higher than some soft plastics, achieving a realistic and non-collapse texture.

Below I show you the tensile elongation ratio %.

| 3.Tensile Elongation Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | ≥10% | 14% | Pass |

| 2# | 16% | Pass | |

| 3# | 16% | Pass | |

Tensile Elongation (%): 10% – The maximum amount of deformation (ductility) that a material can be stretched before breaking. It’s a key parameter: Core advantage! Extremely high elongation means excellent flexibility and damage resistance. When succulents are accidentally bent or squeezed, they can deform significantly to absorb energy and rebound, greatly reducing the risk of brittle fracture, which is a key indicator of durability.

2.2 Flexural Properties – Anti-sagging and shape retention capabilities

Flexural Strength (psi): ≥3600psi psi – The ability of a material to resist bending and breaking. Significance: It is crucial for succulents with long stems or overlapping leaves. Ensure that the stems are not easy to bend and break under gravity or external forces, and the leaves have sufficient support and are not easy to collapse, so as to maintain the designed shape for a long time.

We test 3 piece per standard ASTM D790,all test data meet our internal specification above 3600psi.See below table.

| 4.Flexural Strength Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | ≥3600psi | 4223psi | Pass |

| 2# | 4401psi | Pass | |

| 3# | 5107psi | Pass | |

Flexural Modulus (psi x 10⁶): ≥0.15E6 – The ability of a material to resist elastic deformation due to bending (bending stiffness). The role of this parameter: Works together with tensile modulus. Appropriate bending stiffness makes the stems and leaves upright and stylish, and not prone to excessive bending and sagging due to deadweight or slight touch.

See below table our test result.

| 5.Flexural Modulus Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | ≥0.15E6 | 0.19E6 | Pass |

| 2# | 0.16E6 | Pass | |

| 3# | 0.18E6 | Pass | |

2.3 Specific Gravity – Lightweight advantage

We conduct 3 piece for this test, check below data.

| 6.Specific Gravity Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | 0.9-0.91(g/cm³) | 0.9 | Pass |

| 2# | 0.9 | Pass | |

| 3# | 0.9 | Pass | |

Why it’s a key parameter: The low specific gravity of PP is its signature advantage. Lightweighting brings multiple values: (1) Significantly reduces transportation costs; (2) Easier installation, easy to fix with clay/flower plugs, suitable for hanging scenes; (3) Provides a more natural and burden-free touch.

2.4 ISO Impact-N- against falls and cracks

Check below our real test result.

| 7.ISO Impact-N Test Result | |||

| Sample No. | Criteria | Test Result | Conclusion |

| 1# | ≥10(KJ/m^2) | 55.4 | Pass |

| 2# | 54.6 | Pass | |

| 3# | 47.9 | Pass | |

You can imagine that artificial flowers and succulents will fall off during transportation bumps, daily cleaning collisions, accidental drops, and pets/children’s touches.

High impact strength means extremely strong toughness, not easy to break or chip, significantly reducing the after-sales breakage rate, and is a hard indicator of long-term durability. PP usually is good than PVC and ceramics in impact test.

3.PP faux succulent material properties test SUM

| Property | Test Specification | Our PP | Real-World Advantage |

| Tensile Strength | ASTM D638 | ≥3045(Internal Spec,for better process control) | Resists pulling/tearing |

| Tensile Modulus | ASTM D638 | ≥0.1(Internal Spec,for better process control) | Optimal stiffness |

| Tensile Elongation | ASTM D638 | ≥10(Internal Spec,for better process control) | Won’t shatter when bent |

| Flexural Strength | ASTM D790 | ≥3600(Internal Spec,for better process control) | Prevents stem sagging |

| Flexural Modulus | ASTM D790 | ≥0.15(Internal Spec,for better process control) | Holds shape under load |

| Specific Gravity | ASTM D792 | 0.9-0.91 | lightweight |

| Impact Strength | ISO 180 | ≥10(Internal Spec,for better process control) | Survives drops & impacts |

Keys take away:

These basic mechanical properties are the prerequisites for products to resist daily physical stress and maintain long-term beauty, which is far from being achieved by appearance design alone.

Upcoming:This report focuses on intrinsic structural strength. Please look forward to our special report on weather resistance, which reveals how PP resists UV rays, extreme temperatures and fading, pendulum impact test,heat aging test,as well as environmental and safety certification reports to ensure that your choice is safe and sustainable

4.Artificial flower wholesale data base

Download full data test report

Get the full test data PDF of this article

Consultation: Bulk purchase or customization requirements? Contact the experts [info@artificialflowerwholesale.com]